| |

The Eco-Recycle Material Initiative: |

| Nico's Journey to Sustainable Manufacturing |

| |

| 01. |

Strategic Commitment to Carbon Neutrality |

|

|

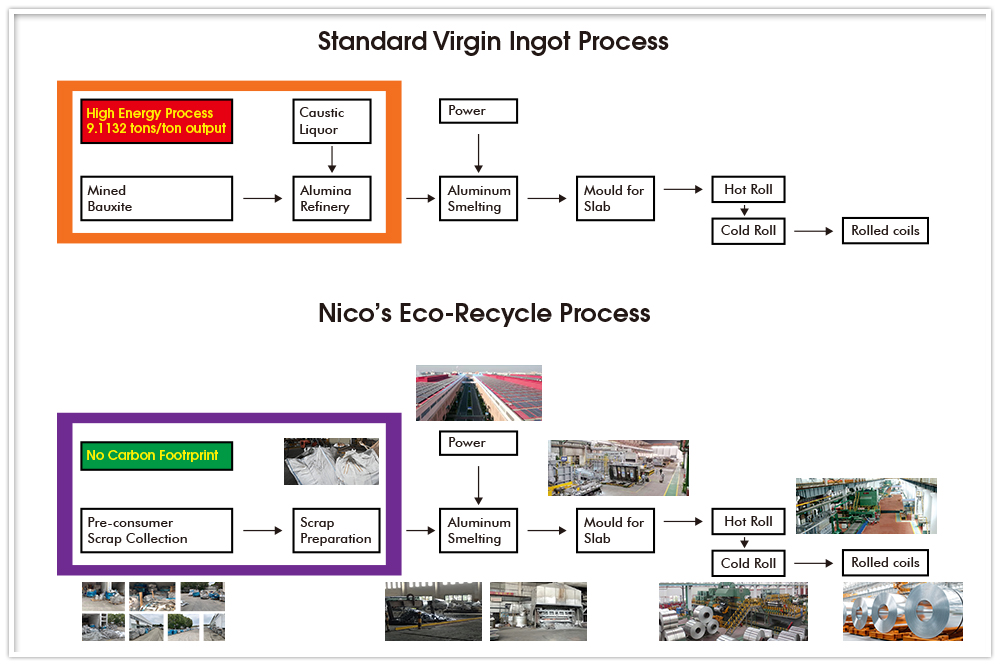

Nico Steel embarked on its Carbon Reduction Journey in 2017, strategically transitioning towards Green Manufacturing. The company has set a clear target to achieve carbon neutrality between 2030 and 2035. To support this goal, management initiated a comprehensive review of its material manufacturing processes, launching a New Business Strategy to transition into a 100% recycled material supplier for aluminium, stainless steel, and copper alloys by 2028. |

|

| |

|

| |

| 02. |

Strategic Commitment to Carbon Neutrality |

|

To fulfill this commitment, Nico focused on sourcing 100% open-market scrap as raw material for casting. Our Recycling Team began development and trials, successfully producing the first batch of A5052 Nico R80 (with a minimum of 80% recycled content) in early 2019. |

| |

|

| |

To ensure our eco-recycling process met international standards, we engaged SCS Global Services, a leading third-party certification body. Following a rigorous review, Nico was officially certified by SCS Global in 2021, becoming one of the first companies in China to receive this recognition under the Global Recycled Standard. |

| |

| |

|

| |

| |

| 03. |

Global Expansion and Risk Management |

|

To strengthen our risk management and global capacity for recycled materials, Nico initiated development and trials for aluminium and copper rod/wire processes at our Thailand plant in 2021. This facility successfully obtained SCS Global Certification for both material types in 2022, further validating Nico’s commitment to sustainable practices across its global operations. |

| |

|

| |

| 04. |

Certified Eco-Recycle Material Portfolio |

|

Since 2019, Nico has continuously refined its casting technology. By 2023, we had expanded our certified portfolio of recycled materials to include the following: |

| |

| |

Nico-China Plant : |

|

Aluminium Alloys: A1050 NicoR100, A1060 NicoR95, A1100 NicoR98, A5052 NicoR80, A5052 NicoR95, A5052 NicoR100, NicoAL50 R80. |

|

Stainless Steel Alloys: SUS 301 NicoR98, SUS 304 NicoR98. |

| |

Copper Alloys: NicoCA2 R95.

|

|

|

| |

Please click on buttons to download the Technical Data Sheets |

| |

|

|

|

|

|

|

|

|

|

A1050 NicoR100 |

|

A1060 NicoR95 |

|

A1100 NicoR98 |

|

A5052 NicoR80 |

|

A5052 NicoR95 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A5052 NicoR100 |

|

NicoAL50 R80 |

|

SUS 301 NicoR98 |

|

SUS 304 NicoR98 |

|

NicoCA2 R95 |

|

|

Nico - Thailand Plant : |

|

Aluminium Alloys: A1100 NicoR98, A5052 NicoR95. |

|

|

Copper Alloys: CU (99.5%) NicoR98.

|

|

| |

Please click on buttons to download the Technical Data Sheets |

| |

| |

|

|

|

|

|

|

|

|

|

|

A1100 NicoR98 |

|

A5052 NicoR95 |

|

CU (99.5%) NicoR98 |

|

|

|

|

| |

All certifications specify a minimum percentage of pre-consumer recycled scrap content. |

| |

| 05. |

Measuring and Minimizing Environmental Impact |

|

|

| Our sustainability efforts extend beyond recycling. In 2022, we began assessing our carbon footprint, achieving ISO 14064 certification in 2023. We initiated Life Cycle Assessment (LCA) studies for selected recycled alloys in 2024. By 2025, these efforts were validated by SGS, confirming that Nico achieves one of the lowest carbon footprints per recycled material in the industry. |

| |

| 06. |

Future Goals : Green Energy and Full |

| |

Transformation |

To further reduce our footprint, Nico will transition to using 50% renewable electricity (green energy) in 2025, with a target of 100% before 2027. |

|

|

|

|

| |

|

|

|

|

| |

| |

|

By 2027, Nico aims to complete its transformation into a fully recycled material supplier. This milestone will align our operations entirely with global sustainability standards, allowing us to contribute meaningfully to the circular economy and deliver high-performance metal alloys with minimal environmental impact. |

| |

Since 2019, Nico has continuously refined its casting technology and expanded its expertise across various metal alloys. This sustained effort culminated in the successful certification of the following recycled materials by 2023: |

| |

Nico - China Plant |

|

A1050 NicoR100 (100% pre-consumer recycled aluminium alloy content) |

|

A1060 NicoR95 (Minimum 95% pre-consumer recycled aluminium alloy content) |

|

|

A1100 NicoR98 (Minimum 98% pre-consumer recycled aluminium alloy content) |

|

A5052 NicoR80 (Minimum 80% pre-consumer recycled aluminium alloy content) |

|

A5052 NicoR95 (Minimum 95% pre-consumer recycled aluminium alloy content) |

|

A5052 NicoR100 (100% pre-consumer recycled aluminium alloy content) |

|

NicoAL50 R80 (Minimum 80% pre-consumer recycled aluminium alloy content) |

|

SUS 301 NicoR98 (Minimum 98% pre-consumer recycled stainless steel alloy content) |

|

SUS 304 NicoR98 (Minimum 98% pre-consumer recycled stainless steel alloy content) |

|

NicoCA2 R95 (Minimum 95% pre-consumer recycled copper alloy content) |

|

| |

Nico - Thailand Plant |

|

A1100 NicoR98 (Minimum 98% pre-consumer recycled aluminium alloy content) |

|

A5052 NicoR95 (Minimum 95% pre-consumer recycled aluminium alloy content) |

|

|

CU (99.5%) NicoR98 (Minimum 98% pre-consumer recycled copper alloy content) |

|

|

|

|

| |

Beyond material certification, Nico is committed to quantifying and reducing its overall environmental impact. We initiated Life Cycle Assessment (LCA) studies for select recycled alloys. These studies, certified by SGS in 2025, confirm that we have achieved one of the lowest carbon footprints per unit of recycled material in the industry. |

| |

|

|

Marketing Enquiry |

| Please contact us at |

| recycle@nico.com.sg |

|

| |